I have been out of industrial activity after completing my graduation for about 2 years, then RVS Quality Certifications Pvt Ltd has changed my outlook on my career. Adopting a course in NDT has helped me launch my career.

Why Phased Array Ultrasonic Testing Is Critical for Modern Quality Assurance

- By: Admin

In the era of advanced technology, quality assurance has moved from the realm of traditional inspection to that of smart technologies with complex designs and sophisticated abilities. Considering the overall design, safety, and integrity of materials today, industries measure these against many precision quality parameters. Among these methods, Phased Array Ultrasonic Testing (PAUT) serves as a key principle within the complex landscape of quality assessments. Key for industries needing absolute perfection are high testing speed, impressive accuracy, and flexibility.

Revolution of Defect Detection

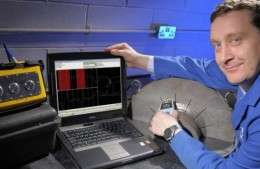

Phased Array upgrades from the conventional type of ultrasonic testing methods by incorporating a series of piezoelectric elements in a single probe; each element can be pulsed separately to transmit sound. This feature allows the operator to electronically control the angle and depth of the sound beam to provide a more complete and precise examination of the material. As a result of its integral imaging system that can produce a real-time high-definition image of the material's internal structure, PAUT ensures that the defect will be detected, which could have been missed by radiography. Benefits accruing to PAUT have continued in its application to this broad spectrum of materials and geometries.

Grooming Expertise Through Specialized Training

As ever, with the technology being largely embraced, there is a growing demand for competent people to operate and interpret PAUT flawlessly. These courses provide wave physics, data interpretation, equipment calibration, and compliance standards to inspectors. Time of Flight Diffraction (TOFD) enhances defect sizing and detection capabilities when paired with PAUT. Certified and well-trained inspectors form the basic asset that keeps quality assurance intact. Phased Array and TOFD Training programs are important for developing this innate knowledge in their respective trainees. On one hand, investing in training boosts the precision of inspection, and on the other, market supremacy comes with consistent delivery of achievable, safe products free from defects.

Setting Safety and Compliance to a New Level

In sectors such as oil and gas, aerospace, and nuclear energy, safety is not just good practice—it is a must. Component failure due to undetected flaws may mean a catastrophic outcome. If this can penetrate our testing protocols, an increased level of successful detection of flaws is expected, plus the potential for compliance with global safety standards. Equipped with Phased Array, the inseparable training element ensures transparent error documentation and merges with the world of digital records. This documentation can track each flaw over time, and compliance reports for stakeholders can be generated in no time. This quality implements transparency and traceability in an industry subjected to regulations.

Furthering NDT Nearly to the Limit

PAUT is indeed a mighty tool for inspections, but two or more NDT methods exist that can complement its properties from another perspective. One such complementary method is Infrared Thermography Services from RVS Quality Certifications Pvt. Ltd. that highlights the thermal imaging to detect infrared patterns to isolate issues such as electrical failures, insulation failures, and mechanical wear—the things that ultrasound waves may not be able to pick up on. Especially effective for predictive maintenance programs, infrared thermography facilitates rapid, non-contact assessments of electrical panels, motors, and building motor components. When done in tandem with PAUT, it provides a whole new quality to inspection efforts without harm, preventing some unexpected replacements.

Achieving Objectivity through Independent Assessment

In high-stakes projects, using just internal inspection teams could raise concerns regarding bias or negligence. These audit services provide impartial views on materials, welds, and components to ensure compliance with the regulatory and contract terms. That is where Third-Party Inspection Services come into play. Including third-party inspectors in the quality chain helps build trust between clients, auditors, and insurance companies. Complementing PAUT with such inspections adds another shield of credibility, for the inspection derives from the nature of the data and evidence. The proof gives a sense of acceptability and enhances confidence for all actors in the chain.

Wrap-Up on the Smart Testing Applicable to Smart Manufacturing

Insofar as those in science and industry seek smarter, reliable, and efficient testing and evaluation methods, the demand for the fallout of the testing only increases as the application of Phased Array finds more resonance due to its formidable precision, digital integration, and sector-wide adaptability. Supported by more well-considered training and bolstered by thermography services, further validated by third-party assessment, PAUT converts from being just one inspection tool to one upon which modern QA systems are built.

RVS is the absolute best value to learn Aerospace NDT Training Course to nurture my skills. I am completely satisfied with how affordable the service they provide. Thanks RVS Team for constant support.

I would like to thank RVS for their time and patience in helping me learn and grow with my NDT courses. I was able to work and learn at the same time, with no pressure. I would recommend RVS to anyone seeking to work and take courses at the same time. I accomplished the course and today I'm a Certified PCN Level II UT engineer.

RVS helped our new hires to acquire the comprehensive training they need, as well as for refresher courses for our current employees. This has worked well for us in obtaining the necessary NDT certifications.

Just a few lines to express my gratitude for your outstanding service over the past year. We would have no issue in referring to your organisation because of your customer devotion and professionalism.

NDT is employed in a wide range of industries, including oil and gas, aerospace, energy, power, nuclear, and transportation, with nearly endless career opportunities. A job in NDT is extremely dynamic, and ongoing training is required.

One of the advantages of a four-year NDT programme is that students can study in a more focused and instructive manner. For graduates, this offers up a plethora of new NDT employment options, including quality assurance, management, engineering design, research, NDT training, and teaching.

Non-Destructive Testing (NDT) Training Courses - Levels 1, 2 and 3.

The PCN (Personnel Certification in Non-Destructive Testing) is a programme that meets the BS EN ISO 9712 requirements for NDT technicians and supervisors. It is founded in the United Kingdom, but it has an impact on a number of countries in the European Union.

6qmb.jpg)

otva.png)