I have been out of industrial activity after completing my graduation for about 2 years, then RVS Quality Certifications Pvt Ltd has changed my outlook on my career. Adopting a course in NDT has helped me launch my career.

What Makes Ultrasonic Testing Services Essential?

- By: Admin

These three factors, safety, precision, and reliability, are among the few that are considered non-negotiable in the fast-moving industrial world of today. Hence, as a result of this, Ultrasonic Testing Services are ranked as one of the most essential instruments for current industries. The use of this futuristic method of inspection locates the source of the problem that is hidden inside the material. It is used for determining the material's strength, and for the prevention of the occurrence of failure, which is unpredictable, it finds a vital place in the mentioned sectors that are oil and gas, aerospace, power generation, manufacturing, and infrastructure.

Why Ultrasonic Testing Stands Out in the NDT World

Without a doubt, ultrasonic testing is the most trusted method to be used for evaluations as it can reveal the concealed defects in the components without causing any kind of damages. Unlike the tests that are only limited to the surface, this testing goes deep inside the materials to give result that are both accurate and reliable. Accuracy of this method is instrumental in a company's risk reduction, quality control, and general production efficiency.

How Ultrasonic Testing Strengthens Structural Safety

From critical pipelines to pressure vessels, internal integrity cannot be compromised. UT ensures that even microscopic defects are identified before they evolve into major hazards. Industries rely on UT because it delivers:

- Accurate thickness measurement, even in areas with difficult access

- Early flaw detection, preventing costly failures

- High-speed testing, ideal for large components

- Greater reliability, thanks to advanced digital evaluation

Its role in safeguarding structural stability makes UT an essential part of routine inspections across industries.

Role of Modern NDT Techniques in Enhancing UT Efficiency

Technological advancements have reshaped the precision and the range of use of ultrasonic testing. Presently, sectors resort to different non-destructive techniques to supplement UT and get a more detailed insight into the material's internal condition. These sophisticated inspection tools are combined to deliver a more comprehensive assessment of parts, equipment and the structural stability of the assets.

In the evolving industrial environment, one cannot overlook the importance of NDT Level 2 Certification Courses, specially designed to equip professionals with strong technical knowledge and hands-on testing expertise.

Why UT is Trusted Across Diverse Industrial Sectors

Without a doubt, the most important feature of ultrasonic testing that cannot be replaced is its versatility. Ultrasonic testing is the chosen method in a vast range of industries, from processes in industrial plants to the different kinds of transportation systems, as it provides extremely accurate and detailed results. These are the three sectors that have been the most advantaged by the use of UT services:

- Aerospace component inspection

- Power generation equipment monitoring

- Petrochemical and refinery pipeline testing

- Heavy machinery evaluation

- Rail and infrastructure component safety

Its ability to detect internal corrosion, cracks, porosity, voids, and weld defects makes UT as a cornerstone of preventive maintenance.

When and Why UT Becomes Critical for Operations

In many industries, downtime can translate into massive financial losses. UT minimizes risks by enabling proactive maintenance and early defect identification. Companies prioritize UT because:

- It prevents catastrophic accidents

- It supports regulatory compliance

- It reduces maintenance costs

- It increases machinery lifespan

- It provides a clear understanding of material integrity

For industries looking to maintain uninterrupted operations, UT becomes a strategic asset.

Precision Inspection with Advanced Technologies

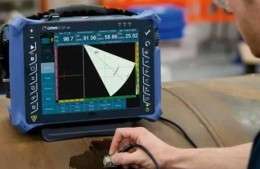

Contemporary UT is not just about locating defects in the conventional way. By advanced technologies, it extends far beyond simple testing and reveals the details of the structures. There is a phenomenal tool like Phased Array Ultrasonic Testing, an extremely complex technique generally employed for the most accurate imaging of the internal condition of the material. Due to the high-resolution scanning, PAUT gives the exact cross-sectional figures, thus it can be the most dependable source for complicated welds, pipelines, and structures which are important.

Why Professionals Trust Any Company

The company focuses on delivering highly accurate inspection outcomes, maintaining quality standards, and ensuring safety across industries. Their expertise and advanced testing infrastructure ensure that organizations receive dependable results every time. RVS Quality Certifications Pvt. Ltd. has become a reliable name in the inspection industry by providing world-class solutions, including Non Destructive Testing Services.

Advantages of Choosing Ultrasonic Testing for Your Industry

UT continues to gain popularity because it is non-invasive and offers unmatched reliability. The benefits extend across production, operation, maintenance, and quality control. Some of its key advantages include:

- Highlyaccurate methods for locating internal defects

- Non-destructive techniques, thus the components are preserved

- Immediate results, therefore, a large number of inspections can be carried out in a short time

- Relatively inexpensive testing, which leads to a decrease in long-term maintenance costs

- Applicable to multiple materials, including metals, composites, and more

These strengths make UT the preferred choice for industries focused on safety and precision.

Conclusion

As industries move towards higher safety norms and stricter quality regulations, the demand for reliable inspection methods continues to rise. Ultrasonic testing has proven itself to be a vital component of preventive maintenance and quality assurance. Its ability to detect invisible flaws, measure material thickness, and provide accurate evaluations makes it essential for ensuring structural integrity and operational safety. With growing technological innovations and wider industrial applications, UT remains at the forefront of inspection methods. It is strong, reliable and indispensable for a safer tomorrow.

RVS is the absolute best value to learn Aerospace NDT Training Course to nurture my skills. I am completely satisfied with how affordable the service they provide. Thanks RVS Team for constant support.

I would like to thank RVS for their time and patience in helping me learn and grow with my NDT courses. I was able to work and learn at the same time, with no pressure. I would recommend RVS to anyone seeking to work and take courses at the same time. I accomplished the course and today I'm a Certified PCN Level II UT engineer.

RVS helped our new hires to acquire the comprehensive training they need, as well as for refresher courses for our current employees. This has worked well for us in obtaining the necessary NDT certifications.

Just a few lines to express my gratitude for your outstanding service over the past year. We would have no issue in referring to your organisation because of your customer devotion and professionalism.

NDT is employed in a wide range of industries, including oil and gas, aerospace, energy, power, nuclear, and transportation, with nearly endless career opportunities. A job in NDT is extremely dynamic, and ongoing training is required.

One of the advantages of a four-year NDT programme is that students can study in a more focused and instructive manner. For graduates, this offers up a plethora of new NDT employment options, including quality assurance, management, engineering design, research, NDT training, and teaching.

Non-Destructive Testing (NDT) Training Courses - Levels 1, 2 and 3.

The PCN (Personnel Certification in Non-Destructive Testing) is a programme that meets the BS EN ISO 9712 requirements for NDT technicians and supervisors. It is founded in the United Kingdom, but it has an impact on a number of countries in the European Union.