I have been out of industrial activity after completing my graduation for about 2 years, then RVS Quality Certifications Pvt Ltd has changed my outlook on my career. Adopting a course in NDT has helped me launch my career.

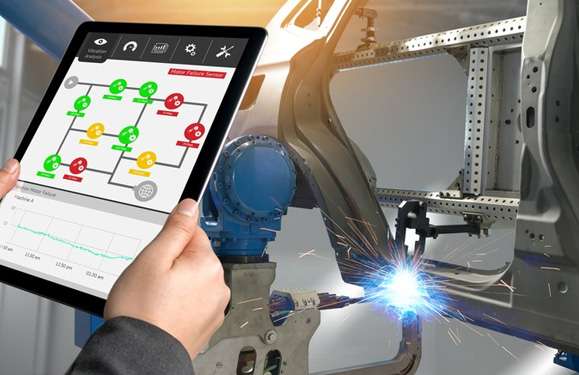

Are CONDITION MONITORING SERVICES Worth the Investment for Small Industries

- By: Admin

The small industry sector still has to justify every investment in terms of its costs and the potential benefits that the project will generate. CONDITION MONITORING SERVICES may appear to be an expensive service initially. RVS QUALITY CERTIFICATIONS PVT LTD,n emphasizes that the long-term gains tend to exceed the short-term costs usually. The conditioning monitoring functions allow the company not only to keep track of the machinery performance but also to spot possible breakdowns in advance, ultimately leading to reduced unproductive hours, which again translates to a cost-saving measure alongside an efficiency gain.

Avoiding Costly Breakdowns Before They Happen

The condition monitoring service comprises the continuous evaluation of the machinery's performance with the use of sophisticated diagnostic tools. The main aim is to detect the wear, misalignment, or other irregularities and take action before they develop into major failures. These services are commonly ignored by small industries as they consider them to be too expensive, but even the most rudimentary monitoring tactics can result in avoiding large production losses. Below are the main advantages:

- Early detection of problems results in the non-occurrence of costly shutdowns in manufacturing.

- Continuous monitoring extends the lifespan of machinery.

- Preventive maintenance costs are lower than those of emergency repairs.

- The risk of accidents due to breakdowns is minimized.

How to Safeguard Your Structures for Long-Term Safety and Reliability?

Although monitoring the machinery is of great importance, the overall safety of a facility is a critical factor as well. Such construction techniques, which are BUILDING STRUCTURAL STABILITY enhancers, provide a conducive atmosphere for the machines to operate safely and securely. The minor factories generally neglect the very fact that machine performance is an indirect effect of nearby vibrations, improper load distribution, or weak structures. To be more precise, the integration of condition monitoring and structural assessments will result in not only the safety of workers and company assets but also a significant reduction of costly incidents.

Advanced Diagnostic Technique

Phased Array Ultrasonic Testing (PAUT) is one of the most powerful tools for condition monitoring methods. High accuracy and precise defect detection are the main benefits of the technology, and engineers can conduct a complete examination of the components even if they are very complicated. In the case where a small industry can allocate a budget for PAUT technology as part of its maintenance practices, it would have the following benefits:

- Cracks or corrosion can be identified in early stages.

- Inspections are done while still keeping the equipment fully functional.

- Maintenance can be based on the actual condition and not on guesswork.

Ensuring Quality and Safety: How Expert Oversight Makes a Difference

In addition to that, small industries that think about condition monitoring should seriously consider the option of teaming up with professionals as a very important aspect. Third-Party Inspection Services provide impartial appraisals of equipment, thus maintenance choices become reliable and efficient. Such services are of utmost help to companies that do not have expert staff. The following points summarize the advantages:

- Specialists detect problems, and their judgment is not influenced by the company.

- Safety and quality standards are complied with.

- Custom industries get hands-on solutions for their particular requirements.

Cost vs. Long-Term Value

The foremost challenge for small-scale industries is the price tag that they have to bear at the beginning. Despite the fact that the initial investment might look huge, in the long run, the savings in cost usually compensate for it. Consider these situations:

- Elimination of costly emergency repairs, which would halt production for several days.

- Decreased costs of replacements due to increased machinery lifespan.

- Reduction of energy waste by operating machines at their peak efficiency levels.

Practical Tips for Small Industries

Small industries aiming to implement the monitoring service can begin by following these practical steps:

- Concentrate on the machines that, if they broke down, would cause the greatest production loss.

- Initially, apply cost-efficient monitoring practices and later upgrade as per requirement.

- Workers must get familiar with the basic reading of monitoring data.

- Major problems can be avoided even with very simple periodic checks.

- Employ external inspection services to strengthen in-house monitoring.

Final Thoughts

For small industries, it may be the case that the concept of investing in services to their advantage is not so easy to notice. However, the benefits are multiple. Among the main reasons are already the prevention of sudden shutdowns, extension of equipment lifespan, better operations and safety, etc. The long-term costs have always been and will be less than the benefits. One could say that initially, small-scale, setting up expert evaluations, and gradually increasing the monitoring capabilities is the way to preserve both the company's assets and its labor.

RVS is the absolute best value to learn Aerospace NDT Training Course to nurture my skills. I am completely satisfied with how affordable the service they provide. Thanks RVS Team for constant support.

I would like to thank RVS for their time and patience in helping me learn and grow with my NDT courses. I was able to work and learn at the same time, with no pressure. I would recommend RVS to anyone seeking to work and take courses at the same time. I accomplished the course and today I'm a Certified PCN Level II UT engineer.

RVS helped our new hires to acquire the comprehensive training they need, as well as for refresher courses for our current employees. This has worked well for us in obtaining the necessary NDT certifications.

Just a few lines to express my gratitude for your outstanding service over the past year. We would have no issue in referring to your organisation because of your customer devotion and professionalism.

NDT is employed in a wide range of industries, including oil and gas, aerospace, energy, power, nuclear, and transportation, with nearly endless career opportunities. A job in NDT is extremely dynamic, and ongoing training is required.

One of the advantages of a four-year NDT programme is that students can study in a more focused and instructive manner. For graduates, this offers up a plethora of new NDT employment options, including quality assurance, management, engineering design, research, NDT training, and teaching.

Non-Destructive Testing (NDT) Training Courses - Levels 1, 2 and 3.

The PCN (Personnel Certification in Non-Destructive Testing) is a programme that meets the BS EN ISO 9712 requirements for NDT technicians and supervisors. It is founded in the United Kingdom, but it has an impact on a number of countries in the European Union.